Product classification

CONTACT US

WECHAT/WHATSAPP :

Skype :

TEL :

0086-371-86525099

0086-15136236223

E-MAIL :

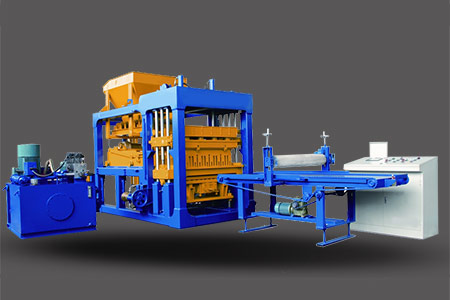

The automatic block making machine applies the high-strength structural steel and special welding technique for its mainframe. The firmness of the mainframe allows the whole machine to come with good rigidity and vibration resistance.

Till now, our automatic block making machine is available with QT4-15B series, QT4-15C series, QT6-15 series, QT6-15B series, QT8-15 series, and QT10-15 series. It has been certified by CE, SGS, TUV, and the like. Our machine has been approved by Bureau Veritas, TUV CERT.

The automatic block making machine applies the high-strength structural steel and special welding technique for its mainframe. The firmness of the mainframe allows the whole machine to come with good rigidity and vibration resistance.The guide pillar of this machine applies the ultrastrong special steel. By virtue of the chromate plated treatment, it perfectly resists torsion and abrasion. Additionally, the four guide pillars together with the ultra-long guide bearing make the pressure head and mould move accurately. This moving system adopts the special device that is good for lubrication, thus avoiding abrasion.

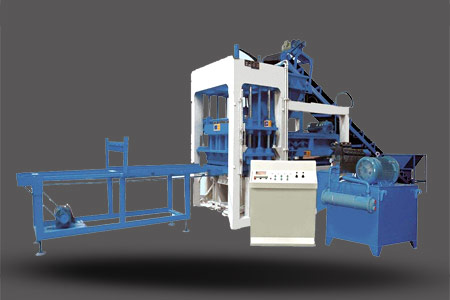

QT5-20 brick maker is a Semi Automatic concrete block making equipment. By changing the moulds, it can produce diverse kinds of concrete wall blocks, such as: insulating block, hollow block, holes block, solid block; and paver blocks, such as: interlock block, Dutch block, curb; as well as concrete members, dry base brick, planter bricks, fence block for parks, air port and wharf, etc.

QT8-15 block brick making machines full automatic : It adopts the PLC operating system,and the action procedures lock with each other,which can guarantees the machine safely and dependablely in the operation procedure.Equipped with color face material feeding device,it could make various color face bricks,through-body Environmental protection bricks,road curb rocks,hydraulic blocks and sod bricks and so on. Multifunction in one machine.Changing molds can produce various kinds of specification porous bricks,standard bricks,hollow bricks,with a double material-feeding machine can produce all kinds of the colored road bricks,grassland bricks,and slope protection bricks etc.

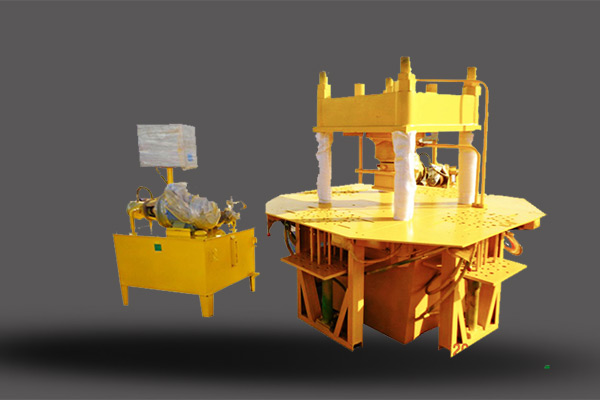

DY-150T Paver Block Making Machine adopts mass flow automatic variable pump and electromagnetic hydraulic valve, with high pressure, rapid lifting, compression automatic bounce back, and adjustable compressing time, high productivity. can produce many kinds of paver and interlock bricks,just exchanging the moulds.DY-150T Paver Block Making Machine using large-flow automatic variable pump and electromagnetism valve to meet strong pressure speedy lifting and pressuring time adjustment.

Automatic Block Making Machine is reasonable in design and compact in structure. For this machine, a programmable controller is adopted so that it can achieve directional librating, converter braking and quick eliminating energy consumption. Additionally, it is no need manual supplying the plates so that the labor intension can be decreased largely.

QT4-20 brick maker is a Semi Automatic concrete block making equipment. By changing the moulds, it can produce diverse kinds of concrete wall blocks, such as: insulating block, hollow block, holes block, solid block; and paver blocks, such as: interlock block, Dutch block, curb; as well as concrete members, dry base brick, planter bricks, fence block for parks, air port and wharf, etc.

Uses high-dynamic proportional and directional valves, which automatically adjust the oil flow and pressure as per specific working requirements, to buffer the hydraulic cylinder when working; uses integrated high-pressure and soft oil pipes, with easy installation; 3) Uses multi-shaft rotating and compulsory feeding, which greatly improves the density and intensity of the blocks, and reduces the feeding time as well.

Hydraulic Paving Block machine uses of advanced dual hydraulic proportional control technology. This could branch of the oil hydraulic system pressure and regulate fuel efficiently.

Technical support and after-sales service team in the Philippines

1. 24 hours online service freely;

2. One year warranty time except for vulnerable parts.

3. Life long maintenance service;

4. Send engineers to install and debug the equipment;

5. Freely train operators to use and maintain skills;

6. Send engineers to fix failure if customers need;

7. Supply all kinds of spare parts;